- Home

- News

- What Parts Can Reciprocating Rotary Spray Cleaning Machine Clean? Applications of Spray Cleaning Machine

What Parts Can Reciprocating Rotary Spray Cleaning Machine Clean? Applications of Spray Cleaning Machine

1) Product use: heavy oil parts surface quickly wash

2) Application scenario: automotive engine, transmission maintenance and cleaning, industrial cleaning

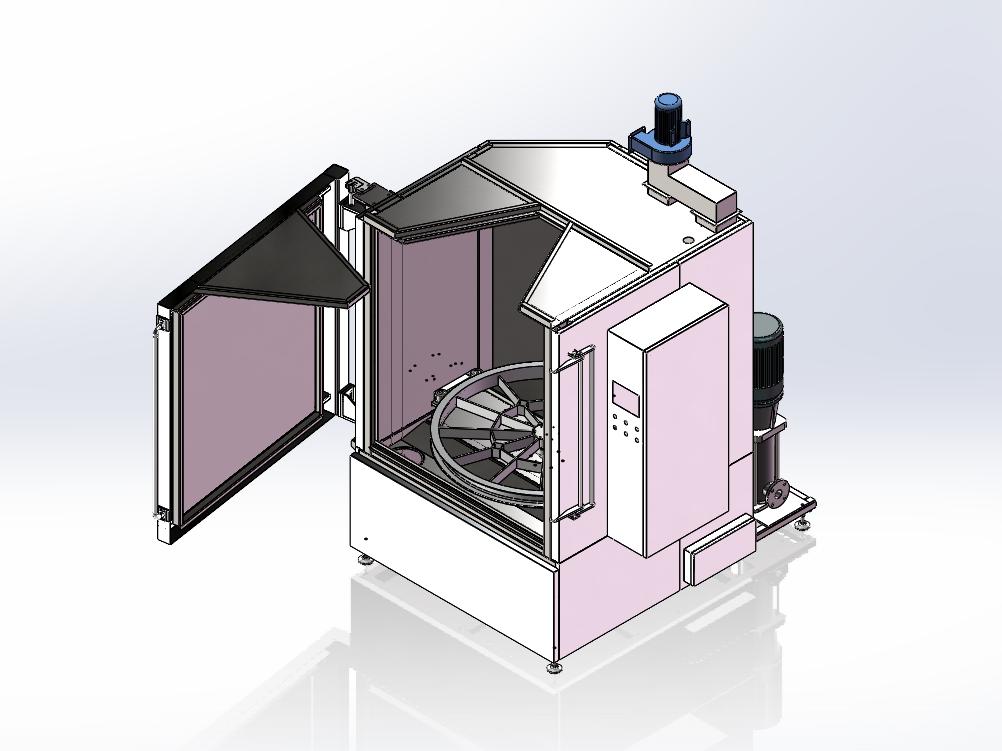

Reciprocating rotary spray cleaning machine is a device used to clean the surface of workpieces. It usually consists of a rotating nozzle and a cleaning device that moves back and forth. The workpiece is placed on the cleaning device, and then the nozzle rotates and sprays detergent or cleaning fluid while the cleaning device moves back and forth to ensure that the entire surface is fully cleaned.

This type of cleaning machine is usually used to clean metal parts, plastic products, glassware and other industrial manufacturing components. It can efficiently remove surface contaminants such as oil, dust, and dirt, and improve the surface quality and cleanliness of the workpiece.

The advantages of Reciprocating rotary spray cleaning machine include high cleaning efficiency, simple operation and uniform cleaning. It plays an important role in industrial production, helping companies improve production efficiency and product quality.

Working Principle Of Rotary Spray Cleaning Machine

The whole machine is centrally controlled by PLC, and all working parameters are set by touching the LCD screen. By hoisting equipment, the operator puts the engine on the rotating tray at the loading level to complete the loading preparation, and starts the cleaning equipment with one click.

After the working door is automatically opened in place, the rotating tray enters the working chamber under the drive of the motor, and the door is closed; Driven by the rotating mechanism, the tray rotates freely, while the pump starts spraying and cleaning; After the cleaning is completed within the set time, the pump stops working, the working door automatically opens in place, and the motor drives the rotating tray automatically out of the working chamber to the loading and unloading level to complete a complete cleaning process.

In addition, the equipment is equipped with multi-level filtration system, pipeline blockage protection system, water level protection system, torque overload mechanical protection device, and fog recovery system, oil-water separation waste oil recovery system and other auxiliary systems. Thus, equipment safety and environmental protection can be easily operated and used by one person. The equipment is suitable for the rapid and efficient cleaning of heavy oil parts during the maintenance of public transport vehicles

How Does Cleaning Spray Work?

The cleaning spray in a reciprocating rotary spray cleaning machine works by using a pump to pressurize the cleaning solution and then spraying it through the nozzles onto the surface of the parts being cleaned. The pump creates the necessary pressure to propel the cleaning solution through the nozzles, creating a fine mist or spray that effectively covers the entire surface of the parts.

In the described machine, the spray is initiated after the rotating tray enters the working chamber and the door is closed. The pump starts spraying and cleaning as the tray rotates freely, ensuring that the cleaning solution reaches all areas of the parts. The spray continues for the set cleaning time, after which the pump stops working.

The spray mechanism is a key component in ensuring thorough and efficient cleaning of the parts. It is important to maintain the proper functioning of the pump, nozzles, and associated components to ensure that the cleaning spray works effectively. Any issues with the spray mechanism, such as pump malfunction, nozzle blockage, or pressure irregularities, can impact the cleaning process and should be addressed promptly to maintain the machine’s cleaning efficiency.

Spray Cleaning System Ensures Efficient and Consistent Cleaning of Engine Blocks

As modern industrial production shifts toward higher levels of automation, efficiency, and environmental responsibility, cleaning systems for large and complex parts—such as engine blocks—are expected to deliver not only thorough results but also intuitive, safe, and cost-effective operation. To meet these requirements, our latest horizontal rotary spray cleaning machine integrates advanced control, monitoring, and safety systems in a compact, operator-friendly package.

One-Touch Cleaning with Full Process Automation

Spray cleaning machine is fully managed by a PLC-based central control unit, with all operational parameters—such as spray duration, flow rate, and water level—easily adjustable via a touchscreen HMI. Once the engine block is loaded onto the rotary tray using standard hoisting equipment and the door is securely closed, the operator simply presses a single button to begin the cleaning cycle.

The motor-driven rotating platform ensures the engine block is evenly exposed to the high-pressure spray nozzles during the cleaning phase. A robust pump system begins circulating cleaning solution immediately, with real-time monitoring of key process variables including flow rate, pressure, liquid level, and motor torque. This ensures optimal cleaning performance while protecting components from abnormal conditions such as overload or dry running.

Once the cleaning cycle is complete, the pump stops automatically and a mist extraction system is activated to remove residual vapors and humidity from the chamber. The entire process—from loading to mist evacuation—is completed automatically in a fully enclosed system, allowing for a safe and consistent operation with minimal manual intervention.

Designed for Operator Safety and Environmental Responsibility

The machine is equipped with a range of safety and auxiliary systems designed for reliability and sustainability:

A multi-stage filtration system ensures that the cleaning fluid remains free of solid contaminants throughout the process.

The pipe clogging detection system protects the spray lines from buildup and blockage, extending equipment lifespan.

A liquid level monitoring system prevents pump dry-run damage and improves operational stability.

An integrated oil-water separation and waste oil collection unit supports eco-friendly operations and simplifies disposal.

All of these systems are integrated seamlessly, allowing the equipment to be safely and easily operated by a single person, without compromising on performance or reliability.

Engineered for Heavy-Duty Engine Parts Cleaning

Our rotary spray cleaning system is specifically engineered for the deep, reliable cleaning of engine components, including parts made from cast iron, aluminum alloys, and various coated materials. These engine parts often accumulate multiple types of industrial contaminants such as machining chips, cutting oils, carbon buildup, coolant residues, and handling-related impurities.

Traditional cleaning systems often struggle to remove these complex layers of contamination, especially on heavy-duty and irregular-shaped parts. In contrast, our solution combines 360-degree mechanical rotation, high-pressure spray jets, and real-time monitoring sensors into a single, fully automated process. This integration allows for consistent cleaning performance, even across complex geometries and surfaces—making it ideal for high-throughput engine block washing or remanufacturing lines.

(A pallet for carrying heavy objects)

Scalable and Sustainable Industrial Parts Cleaning System

Designed with scalability in mind, this automated rotary spray cleaning machine features a modular structure and adjustable process control, making it suitable for a wide range of engine cleaning applications—from new engine assembly lines to remanufacturing workshops and repair depots.

Whether used as a standalone parts washer or integrated into a fully automated production line, this system delivers powerful performance with minimal operator involvement. It’s an ideal solution for automotive manufacturers, off-road equipment builders, and industrial engine producers who demand repeatable, high-standard cleaning prior to coating, sealing, inspection, or final assembly.

The ability to effectively remove oil residues, carbon films, and microscopic particles from large engine components ensures that every cleaned part is production-ready—free of contaminants that could compromise downstream processes or product quality.

|

Model |

TS-L-WP1200 |

TS-L-WP1400

|

TS-L-WP1600

|

TS-L-WP1800 Customized |

| Dimension(LxWxH )mm |

2000×2000×2200 |

2200 x 2300 x 2450 |

2480×2420×2550 |

2700× 2650× 3350 |

| Turntable Dimeter mm |

1200 |

1400 |

1600 |

1800 |

| Cleaning height mm |

1000 |

1000 |

1200 |

1800 |

| Load capacity |

1ton |

1ton |

2ton |

4Ton |

| Rated Power |

35 |

35 |

39 |

57 |

| Heating power KW |

27 |

27 |

27 |

33 |

| Pump KW |

7.5 |

7.5 |

11 |

22 |

| Cleaning pressure BAR |

6-7 |

6-7 |

6-7 |

6-7 |

| Liquid storage tank volume |

800ltr. |

1100ltr. |

1350ltr. |

1650ltr. |

| Cleaning flow( L/min) |

400 |

400 |

530 |

600 |

| N.W./G.W. |

1200/1800 |

1400/2000 |

1600/2200 |

2400/3500 |

| Packing size | 2200× 2380×2650 | 2400×2450×2700 | 2650×2540×2780 | 2700× 2650× 3350 |

| H.S. Code | 8424300000 | |||

TENSE specializes in industrial production cleaning equipment; More than 20 years of cleaning experience in the industry. Our products include ultrasonic cleaning equipment, multi-functional water-based cleaning equipment, hydrocarbon cleaning equipment, aqueous particle cleaning equipment, high-pressure cleaning equipment, dry ice, gas ice cleaning equipment, plasma cleaning equipment, fluid purification and industrial wastewater treatment equipment.Solve customer cleaning problems.

We cordially invite you to visit our official website www.china-tense.com and get in touch with us. Your inquiries and interactions are highly anticipated!