What Are The Advantages Of Ultrasonic Cleaning Machine? How Do Ultrasonic Washers Work?

Ultrasonic Washing Equipment have quickly become the solution of choice for many industries that require a thorough, efficient cleaning process. These machines use ultrasonic waves to clean objects and have many advantages. In this blog, we discuss the advantages of Ultrasonic Cleaning Equipment and how they are revolutionizing the cleaning industry.

One of the main advantages of Ultrasonic Cleaning Equipment is their ability to reach the tiniest of crevices. Ultrasound waves from these machines create tiny bubbles that implode on contact, creating powerful shock waves. These shockwaves can penetrate every nook and cranny of an object, including intricate designs and hard-to-reach areas. As a result, Ultrasonic Cleaning Equipment can remove stubborn dirt, contaminants and debris that are often difficult to remove with traditional cleaning methods.

Efficiency is another significant advantage of using an ultrasonic cleaner. Unlike manual cleaning or other traditional methods, Ultrasonic Cleaning Equipment perform tasks quickly and without constant human intervention. Simply place the object to be cleaned in the chamber, select the desired cleaning settings and the machine will take care of the rest. This frees up valuable time and resources that can be allocated to other important tasks, increasing overall productivity.

An important aspect of an ultrasonic cleaner is its ability to clean delicate or sensitive items. Many fragile objects or materials, such as jewelry, delicate parts or electronic components, require careful cleaning to avoid damage. Ultrasonic Cleaning Equipment excel in this area, providing a gentle yet powerful cleaning process. The tiny air bubbles produced by the ultrasonic waves do not cause any harm to delicate surfaces, ensuring thorough cleaning without compromising the integrity of the object.

Ultrasonic Cleaning Equipment also offer a safer and more environmentally friendly solution than other cleaning methods. Cleaning uses water-based solutions or mild detergents without the use of harsh chemicals that are harmful to the environment. Additionally, precise and efficient cleaning operations reduce overall water usage, making it a more sustainable choice in the long run.

The versatility of Ultrasonic Cleaning Equipment is another advantage worth mentioning. These machines can hold various objects and materials, making them suitable for various industries. Ultrasonic Cleaning Equipment can effectively clean everything from medical and laboratory equipment to auto parts and jewelry. Their adaptability and customization options meet specific cleaning requirements, ensuring the best results for each application.

HOW DO ULTRASONIC WASHERS WORK?

Ultrasonic cleaning utilizes high-frequency sound waves that are transmitted through a liquid to effectively cleanse the surface of submerged components. Typically operating at a frequency of 40 kHz, these sound waves agitate a liquid solution consisting of water or a solvent, resulting in the formation of cavitation in the solution’s molecules.

How does the water-oil circulation system improve the performance of ultrasonic cleaning machines?

ultrasonic technology apart is its broad compatibility with various materials and applications. These systems are used to clean everything from metal automotive parts and surgical tools to ceramic, plastic, and glass components in electronics or laboratory settings. Their ability to adapt to different shapes, contamination types, and production environments makes them a highly versatile and future-ready solution. Whether integrated into an automated assembly line or used as a standalone unit in a clean room, ultrasonic cleaning equipment offers a reliable, scalable answer to modern industry’s growing demand for precision and performance.

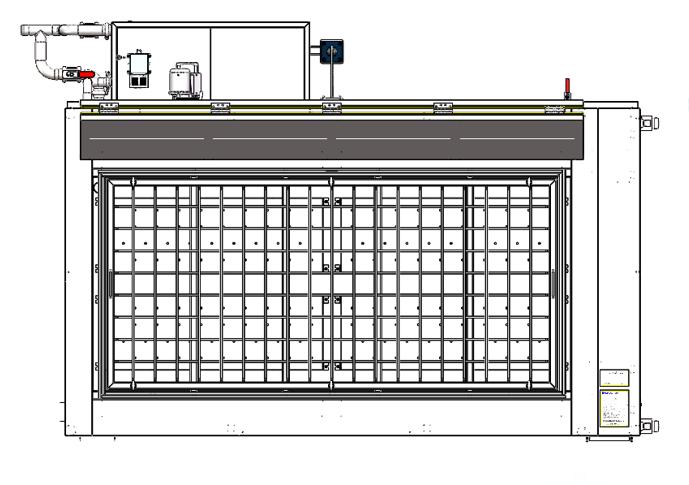

as the complexity of contaminants increases, so does the need for smarter fluid management. This is where our TS Series A-Type Single-Tank Ultrasonic Cleaners, such as the Ultrasonic Cleaner TS-3600A, offer a powerful advantage: water-oil circulation system.

During operation, contaminants are continuously separated from the cleaning solution. Oil is skimmed and collected into a waste reservoir, while clean water is circulated back into the tank—maintaining fluid purity, stabilizing ultrasonic performance, and preventing recontamination of cleaned parts. This closed-loop system significantly reduces fluid replacement frequency, lowers operational costs, and improves ennmental sustainability.

Oil skimmer:

During cleaning, oil, grease and light dirt will raise to the surface of the water. If this is not removed, the cleaned components will become dirty as they are raised up through the surface.

The surface skimmer function flushes the water surface after each cleaning cycle, before the basket is raised out of the tank. This ensures completely clean components after each cleaning cycle. The dirt, oil & grease removed from the surface is collected in the oil skimmer where oil and grease is skimmed off.

Whether you’re cleaning aluminum alloy cylinder heads, cast-iron housings, or coated gear units, the cavitation process inside the TS-A machines reaches deep into blind holes, threads, and internal cavities—removing what manual scrubbing or traditional spraying methods simply can’t.

These units are especially well-suited for automotive and machinery plants, engine rebuilding workshops, and maintenance centers where components carry multi-layer contaminants and production timelines are tight. By extending cleaning fluid life and minimizing maintenance downtime, the TS-A series helps operators achieve higher throughput without compromising on cleaning quality.

nother hallmark of the TS-A series is its pneumatic door mechanism, enabling efficient front-facing access for operators managing heavy and awkward parts. The door opens and closes with smooth, compressed-air actuation, making high-frequency operations safer and more ergonomic. Whether used in standalone applications or integrated into automated lines, these machines are designed for repeatability, durability, and low human intervention.

The filtration system in ultrasonic cleaning machines plays an indispensable role in ensuring cleaning effectiveness, extending equipment service life, and improving work efficiency. By selecting an appropriate filtration method, contaminants in the cleaning solution can be effectively removed, ensuring the continuity and stability of the cleaning solution, thereby enhancing cleaning quality and reducing operational costs. With the continuous development and advancement of filtration technology, the filtration systems of ultrasonic cleaning machines will become increasingly efficient and [sensitive word] in the future, providing superior cleaning services to various industries.

From engine remanufacturing and automotive overhaul to precision mechanical assembly, the TS Series A-type models offer industrial clients a smart, scalable solution that balances cleaning depth, fluid longevity, and operator safety—all while lowering total cost of ownership.