TRANSMISSION INDUSTRIAL ULTRASONIC CLEANER

Ultrasonic cleaning systems designed specially for professionals of the motoring world. At Tense, we know and understand the cleaning needs of the industry, so we have developed the most efficient cleaning system, ensuring an optimum quality in the cleaning processes of our clients.

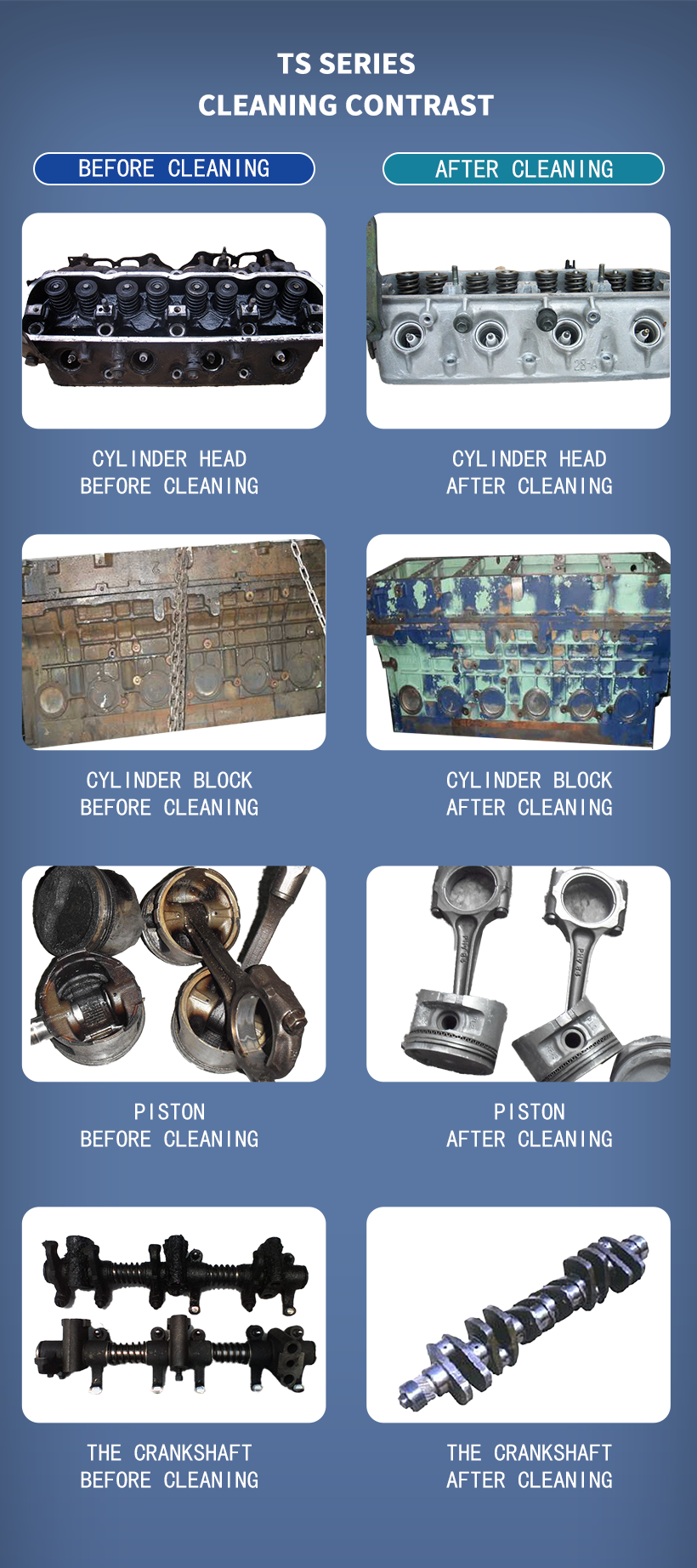

Equipment from the TS series offer indisputable advantages over traditional cleaning systems. They are the best choice for degreasing, decarbonising and descalingengine pieces and components since they achieve the best results for being able to access the most hard-to-reach pieces regardless of their complexity and with no effort.

{TS-4800B}

| Volume | 430 liters | 113gallons |

| Dimensions (L×W×H) | 1660 x 1220 x 910mm | 65”×48”×35” |

| Tank size (L×W×H) | 1200 x 600 x 600mm | 47″×23″×23″ |

| Useful size (L×W×H) | 1120 x 560x 460mm | 46″×22″×19″ |

| Ultrasonic power |

4.8 Kw |

|

| Ultrasonic frequency |

28KHZ |

|

| Heating power |

10 Kw |

|

| Oil skimmer (W) |

15 |

|

| Circulating pump power ( W) |

200 |

|

| Packing Size (mm) |

1500×1250×1080mm |

|

| G.W. |

450KG |

|

1) The general working temperature of the ultrasonic cleaner is about 55 degrees (131℉), and the long-term working temperature should not exceed 75 degrees(167℉);

2) It is forbidden to turn on the ultrasonic and heating functions without adding liquid;

3) The parts need to be put into the cleaning tank for cleaning through the basket, and it cannot be directly put into the working tank for cleaning;

4) When the parts are placed and taken out of the cleaning tank, turn off the ultrasonic work first;

5) The choice of cleaning detergent should satisfy 7≦Ph≦13;

6)The moving device of the equipment is only used for the moving position of the tank body when it is vacant, and cannot be used to fill the liquid or clean the parts frequently.

{movie}

The high-efficiency cleaning effect and low-cost investment of industrial single-tank ultrasonic cleaning equipment are very popular with customers. This series of cleaning equipment is widely used in some auto repair shops, engine and gearbox maintenance companies and some construction machinery maintenance companies. Through cleaning the processing of the machine can bring a very good effect to the surface of the aluminum alloy metal, and even restore the luster of the surface of the new part. It has a very obvious effect on the cleaning of carbon deposits in the exhaust holes of the engine cylinder head; it also has a very obvious cleaning effect on some very precise parts in the gearbox, such as valve plates.

Common customer groups Car maintenance, boring cylinder grinder center, gearbox maintenance,remanufacturing maintenance industry.