Several factors for the effect of ultrasonic

(1)Ultrasonic frequency: the lower the frequency, the better the cavitation, the higher the frequency, the better the refraction effect. For simple surface ultrasonic cleaning, low frequency such as 28khz should be used, and high frequency should be used for complex surface and deep hole blind hole ultrasonic cleaning; such as 40hkz.

{photo}

(2) Power density: The higher the power density, the stronger the cavitation effect, the better the ultrasonic cleaning effect, and the faster the cleaning equipment. High power density should be used for workpieces that are difficult to clean, and low power density should be used for precision workpieces.

(3)Cleaning temperature: Ultrasonic cavitation is best at 40°C to 60°C. The higher the temperature, the more conducive to the decomposition of dirt, but when the temperature reaches 70 ℃ ~ 80 ℃, it will affect the effect of ultrasonic waves and reduce the cleaning effect. Combining various factors, it is generally recommended that the temperature to be cleaned be set at 60-65 degrees Celsius. In this way, the cleaning effect and the empty talk effect of ultrasonic waves are relatively optimal.

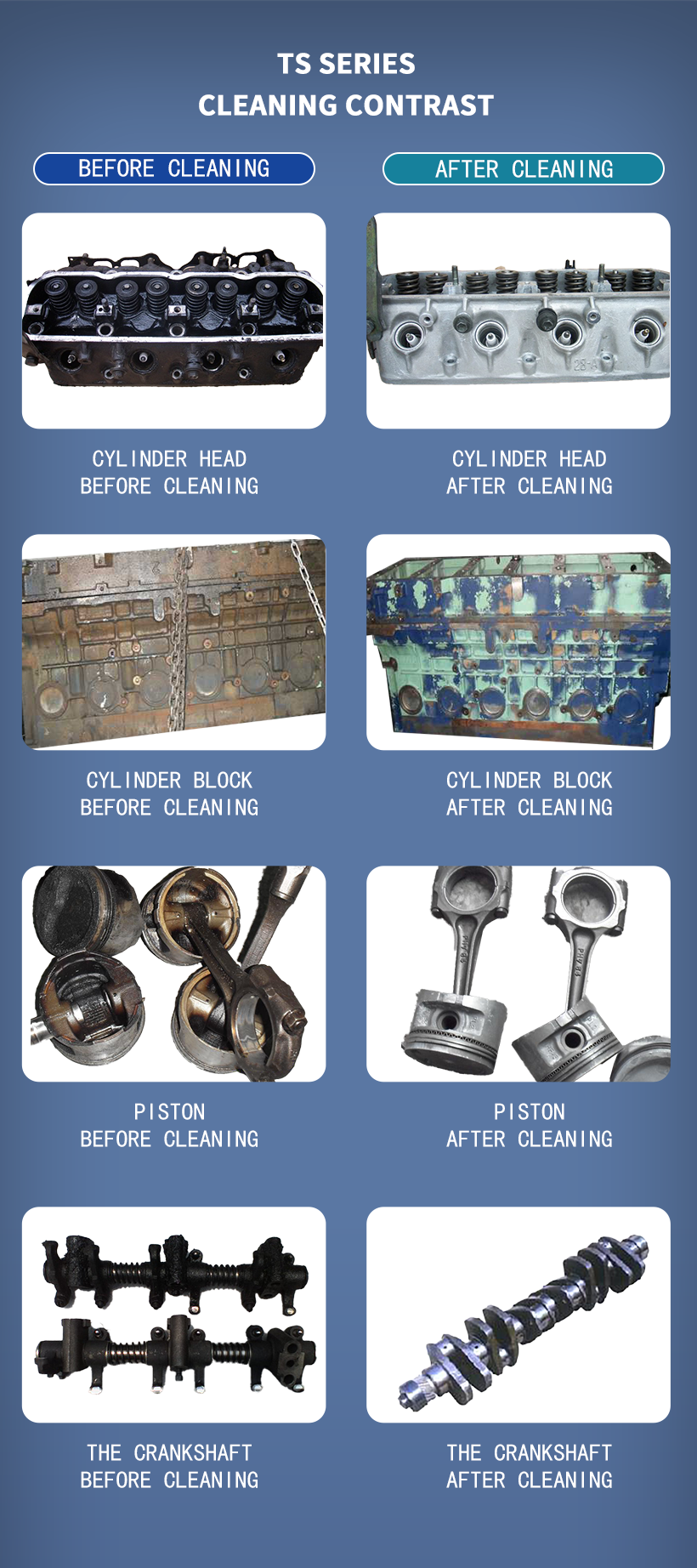

(4)Cleaning time: the longer the ultrasonic cleaning time, the better the cleaning effect, except for special materials: The general cylinder cleaning time is recommended to be about 30-40 minutes, and the piston cleaning needs about 15-20 minutes; it is determined according to the degree of oil pollution and carbon deposition.

(5) The type of solution (medium): According to the different objects to be cleaned, choose the appropriate cleaning medium, such as powder; the general recommended addition ratio is about 3%~5%; there are also liquid cleaning media;

The addition ratio is about 10%. In order to achieve the best ultrasonic cleaning effect.