How to choose a transmission parts cleaning machine

How to choose a transmission parts cleaning machine

During the maintenance process of the gearbox, the cleanliness of the parts will directly affect the quality of the gearbox; so how to clean the gearbox parts during the maintenance process is very important. How to choose a suitable cleaning machine to clean these parts requires serious consideration by practitioners. Here are some sharing based on our experience:

-

The disassembled parts of the gearbox assembly include:

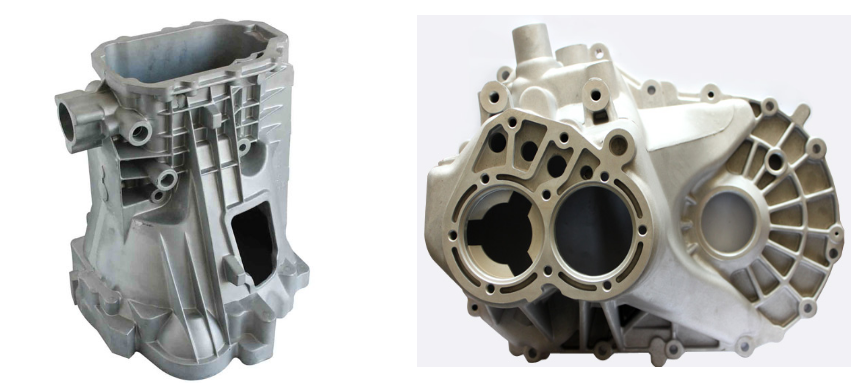

1.1 Shell parts: the outer surface is some sludge and fine sand. During the cleaning process, it is necessary to prevent these pollutants from contaminating other internal parts, because the particles entering the internal flow channel are fatal to the gearbox

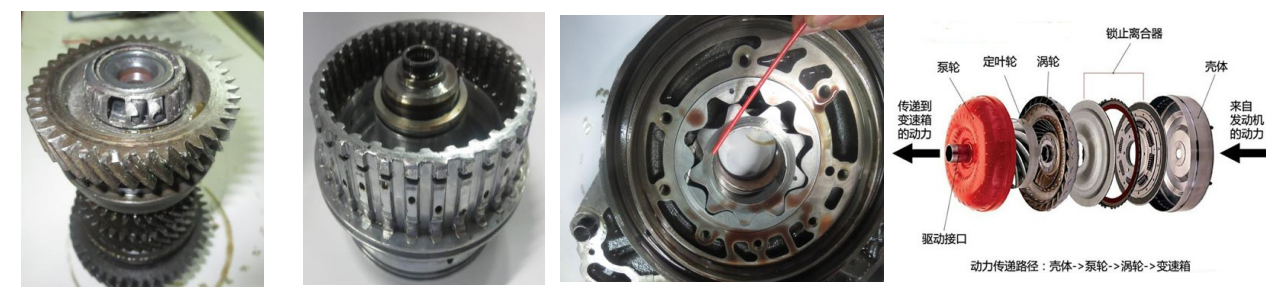

1.2 Internal general parts: gear set, magnetic drum, clutch, etc.; the main pollutants are transmission oil and metal dust, etc., the shell after the outer surface cleaning can be mixed and cleaned

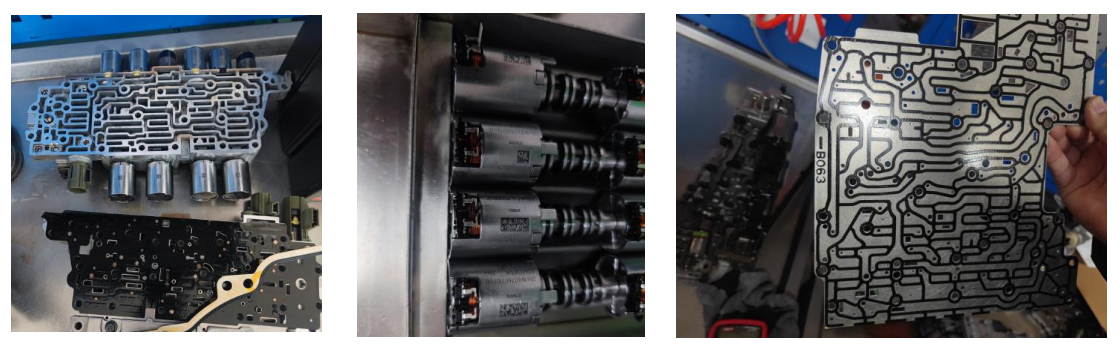

1.3 Precision parts: valve body, valve plate and some solenoid valves; such parts are relatively precise, so it is best to use independent cleaning equipment, even for some special parts, it is not suitable for water-based cleaning medium, but hydrocarbon-based Solvent as cleaning medium

- Recommended cleaning plan

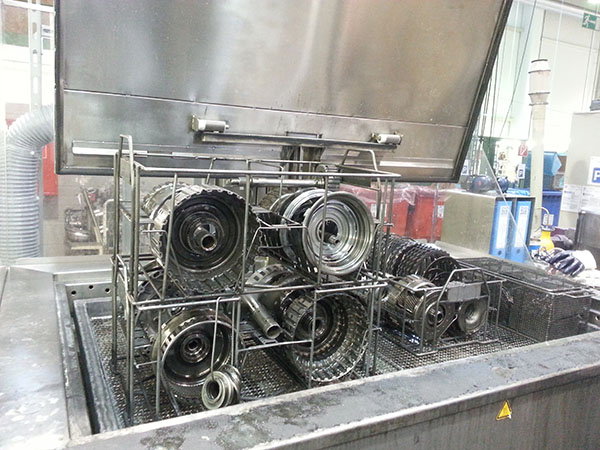

2.1 Use the TS-P series spray cleaning machine for the initial cleaning of the gearbox casing and general internal parts; (Note: If the casing is to be cleaned with other parts, it is recommended that the outer surface of the casing be cleaned first to avoid the outer surface Dirt contaminates other parts)

2.2 Use an ultrasonic cleaning machine for fine cleaning of parts to improve the cleanliness of parts, especially the surface of aluminum parts after ultrasonic cleaning is closer to the primary color of the metal.

Cleaning effect

2.3 On-site case description: ZF gearbox China remanufacturing factory, products include pre-disassembly cleaning, parts cleaning, pre-assembly cleaning, valve plate cleaning, etc.图片:(采埃孚变速箱再制造)