ENGINE BLOCK REPAIR ULTRASONIC WASHING MACHINE

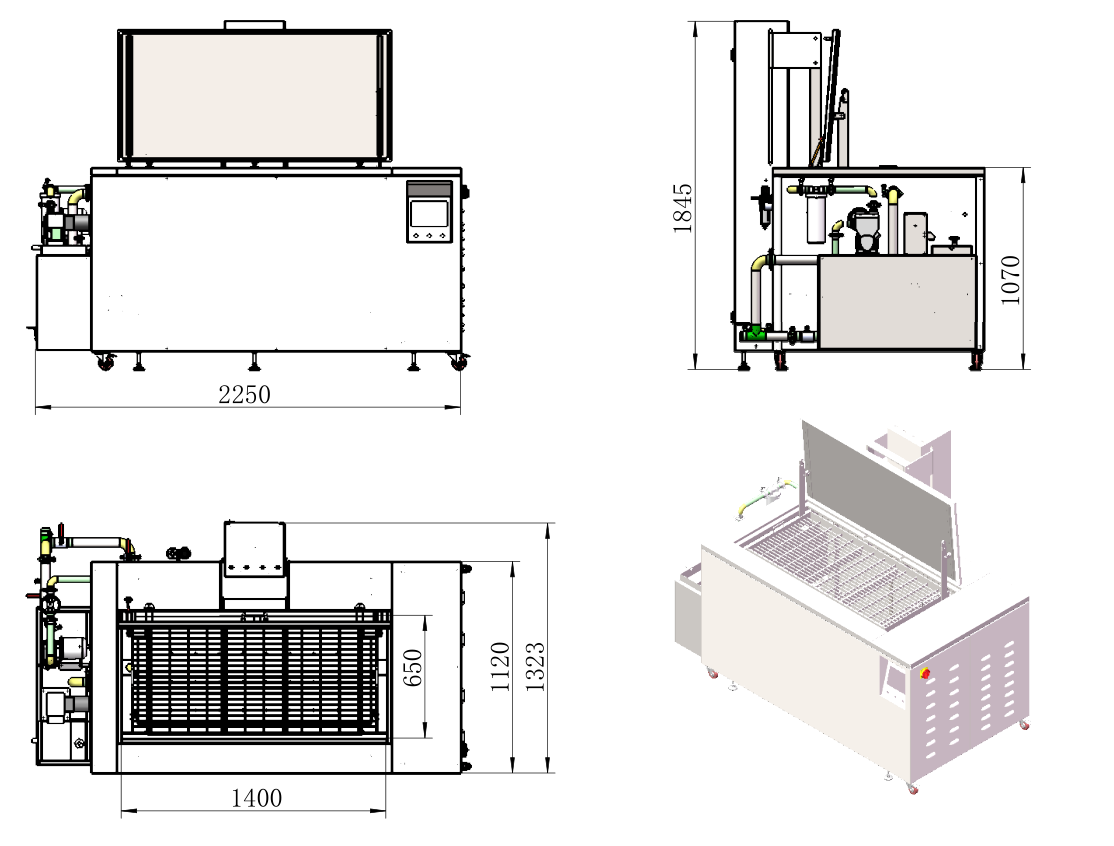

Description

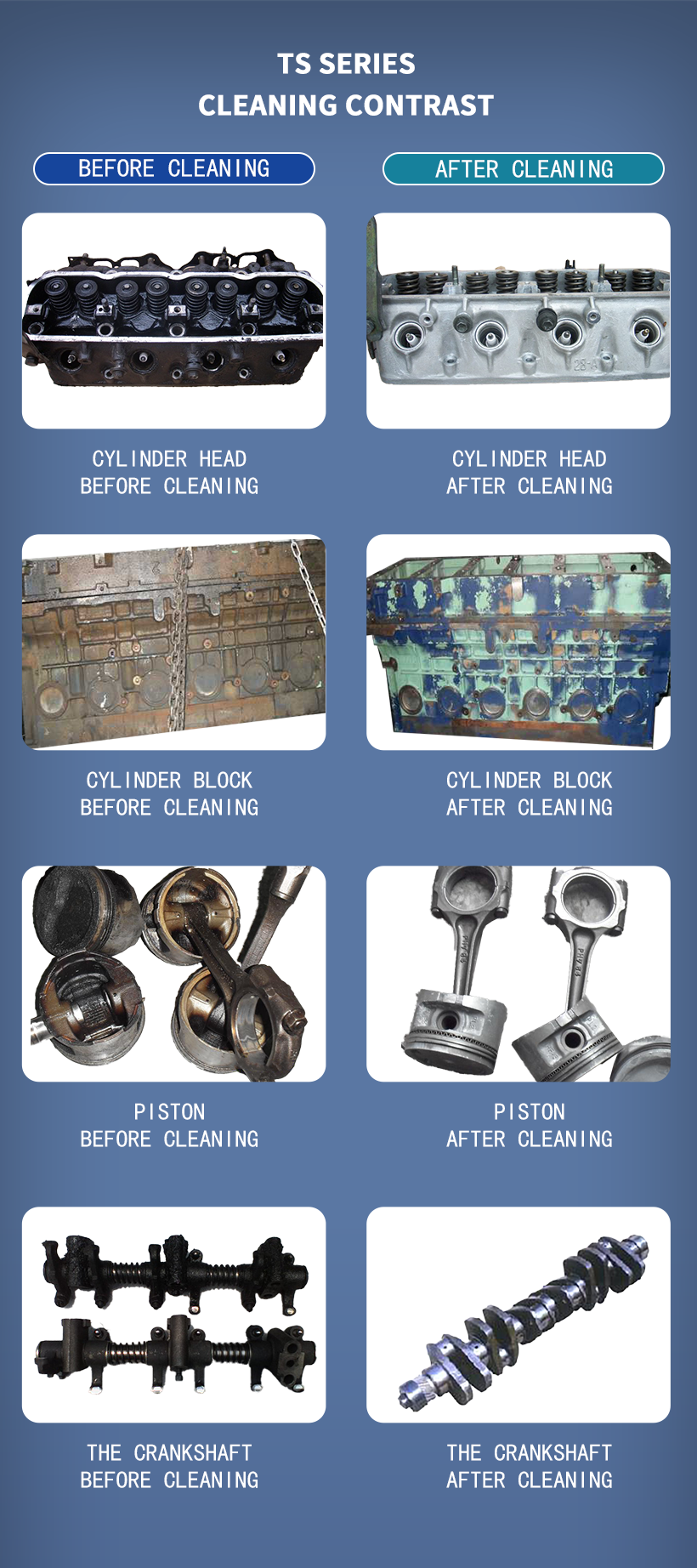

Offers a solution to larger industrious cleaning requirements, including the cleaning of engine parts like intercoolers, valve spindles, fuel injectors, cylinder heads, pistons and heat exchangers.

{TS-UD600}

Features

Specification

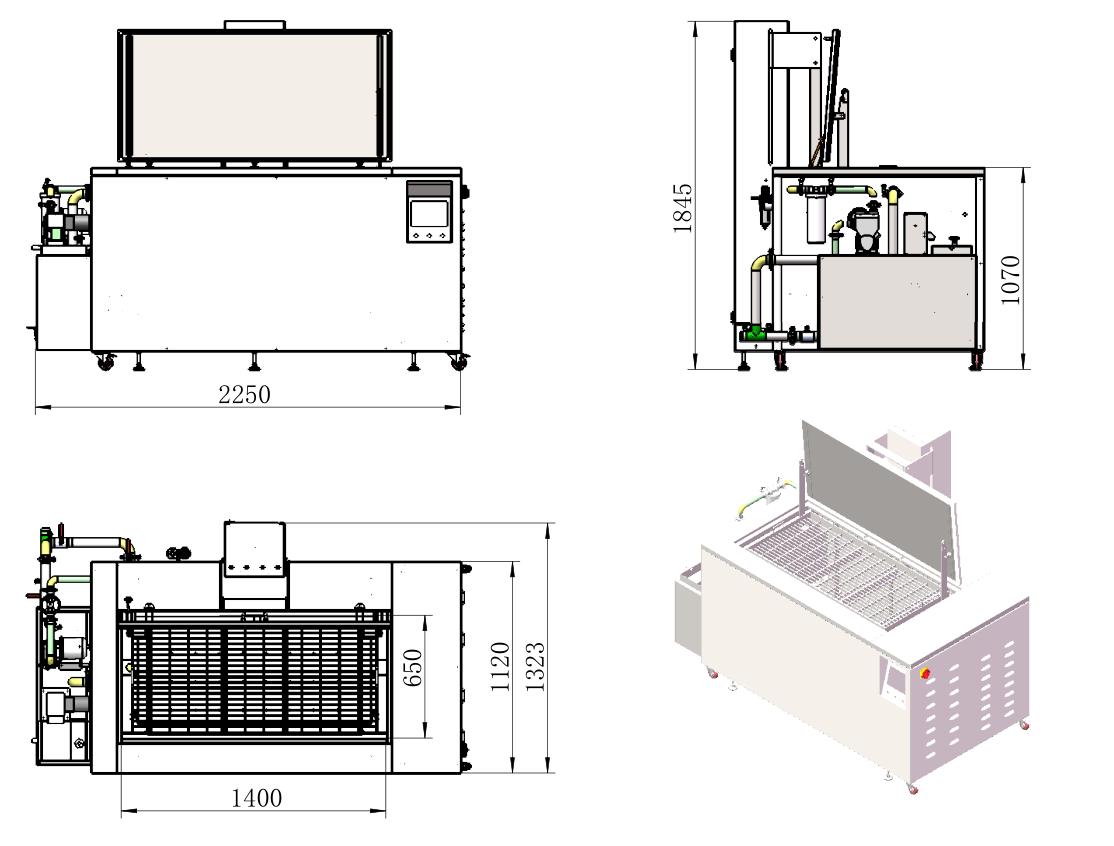

| Model |

TS-UD600 |

| Capacity |

640ltr. 169gal |

| Useful size |

1300×600×480mm 51”×23.6”×18.8” |

| Dimension |

2250×1323×1845mm 89”×52”×73” |

|

Load capacity |

300kg 660lbs

|

| Heating |

22kw |

| Ultrasound |

8.6kw |

| Ultrasonic frequency |

28khz |

| pump power |

200w |

| Oil skimmer power |

15w |

| Transducer Qty. |

96 |

| G.W. |

790kg |

| Packing size |

2350×1400×1970 |

Maintence

* Regularly check whether there baskets sealing off and do trimming

* Check all piping for leaks phenomenon , the timely processing

* Regular cleaning tank oil , extend life and cleaning agent consumption.

* Monthly Check control cabinet lines, especially the line contactors are tightened , and timely manner ;

* Monthly testing whether leakage protection failure to ensure safety

* Regular cleaning of the ash layer circuit boards , to keep clean

* Regular cleaning of the heating tube outer surface dirt , improve the heating efficiency and prolong life

* Add lubricating oil regularly to the slider

* Regular inspection of cylinder hole switch, make sure it is induction, or no damage.

* Regularly give air duplex drainage and filling lubricating oil

Applications

The dynamic ultrasonic cleaning machine adds more functions on the basis of single-tank ultrasonic, making the equipment more intelligent and humanized, and making it easier for operators to cooperate with cleaning work. Tense cleaning equipment can be used for engines and gearboxes , cleaning treatment of supercharger parts remanufacturing and maintenance process; this cleaning machine is very suitable for docking with automation equipment to meet the needs of online cleaning, and can also be combined with multiple equipment to achieve assembly line cleaning; currently we are in Denmark, Colombia, Dubai and the Philippines have long-term and stable cooperative distributors; products are exported to many countries.

TS-UD Series:Integration of Advanced Cleaning Technologies in a Single Platform

In today’s high-precision manufacturing sectors — including automotive, aerospace, mechanical engineering, electronics, optics, and medical technology — component cleanliness is more critical than ever. As parts move through increasingly sensitive downstream processes, even the smallest contamination can lead to defects, reduced product performance, or process failure.

While particle removal has long been the focus of industrial cleaning, the industry is now seeing a clear shift: film-type residues are emerging as a new challenge. These residues — including machining oils, corrosion inhibitors, mold release agents, silicones, and even fingerprints — can significantly impair subsequent processes such as coating, welding, bonding, and sealing.

This evolution in cleaning requirements is driven by advances in production, joining, and coating technologies, as well as new materials and material combinations. To meet these demands, manufacturers are turning to ultrasonic cleaning systems like the UD-300, which offer deep, precise, and consistent cleaning at a micro level — even in complex geometries and hard-to-reach areas.

With the ability to remove both particulate and film-like contamination, ultrasonic cleaning has become a vital step in ensuring process reliability, reducing rejects, and maintaining high product quality across industries.

TS-UD300 Industrial Ultrasonic Cleaner: Efficient, Intelligent, and No-Dead-Angle Cleaning Solutions

In the large-scale cleaning needs of automotive parts, machined parts, aluminum alloys, glass, ceramics and other materials, cleaning efficiency, deep cleaning capabilities and automation have become key indicators. To this end, we have launched a new generation of intelligent ultrasonic cleaning equipment-TS-UD300, which meets the stringent requirements of modern industrial production for high-quality cleaning processes.

Specification

| Model | UD-300 |

| Capility(KG) | 200 |

| Volume(ltr) | 420 |

| Dimension (cm) | 207×108×169 |

| Useful Size(cm) | 110×50×42 |

| Heating (KW) | 10.0 |

| Ultrasonic Power(KW) | 3.0 |

| Pump Power(W) | 200 |

| Oil skimmer (W) | 15 |

| Main connection | 380V/60HZ/3Phase |

| Transducer Qty. | 68 |

| Packaging size(CM) | 217×127×187 |

| G.W.(KG) | 650 |

The cleaning process adopts fully automatic control, which is easy to operate and efficient:

The operator only needs to place the parts on the material bracket through the lifting equipment, and after starting the equipment with one button, the parts will automatically descend and sink into the aqueous solution in the cleaning tank.

During the cleaning process, the cylinder drives the slider to drive the bracket to perform reciprocating lifting and lowering movements to ensure that every corner can be evenly covered by ultrasound to achieve no-dead-angle cleaning.

After the cleaning is completed, the parts automatically rise out of the liquid surface, completing a complete and efficient cleaning process.

Core advantage configuration:

Multi-stage filtration system: effectively extend the service life of cleaning fluid and improve cleaning efficiency

Oil-water separation and waste oil recovery system: green and environmentally friendly, energy saving and emission reduction

Water level protection system: intelligent monitoring to avoid dry burning risk

Automatic water replenishment and reservation function: improve the degree of operation automation and save manpower

High-frequency ultrasonic system: precise energy conduction, adapt to the cleaning of parts with complex geometric structures

Whether it is to remove oil stains, cutting fluids, oxide films, or to prepare for subsequent coating, electroplating, welding and other processes, TS-UD300 can provide stable, controllable and reproducible cleaning effects, suitable for batch and high-standard industrial production scenarios.

TS-UD300, creating a truly efficient cleaning process, is your ideal choice for improving product quality and production efficiency.

For different materials and cleaning targets, the TS-UD series equipment has a highly flexible structural design, which can flexibly adjust and expand functional modules according to specific process requirements. Whether it is high-frequency ultrasonic cleaning, multi-stage filtration system, or auxiliary equipment such as automatic water replenishment, liquid level monitoring and high-precision temperature control, they can be flexibly integrated into the system. In addition, the equipment supports a variety of automated loading and unloading solutions to meet the diverse needs from independent operations to fully automatic production lines, ensuring that every cleaning is accurate and efficient.

TENSE specializes in industrial production cleaning equipment; More than 20 years of cleaning experience in the industry. Our products include ultrasonic cleaning equipment, multi-functional water-based cleaning equipment, hydrocarbon cleaning equipment, aqueous particle cleaning equipment, high-pressure cleaning equipment, dry ice, gas ice cleaning equipment, plasma cleaning equipment, fluid purification and industrial wastewater treatment equipment.Solve customer cleaning problems.

We cordially invite you to visit our official website www.china-tense.com and get in touch with us. Your inquiries and interactions are highly anticipated!