Application range of ultrasonic cleaning equipment

Among all the current cleaning methods, ultrasonic cleaning is the most efficient and effective one. The reason why ultrasonic cleaning can achieve such an effect is closely related to its unique working principle and cleaning method. The common manual cleaning methods undoubtedly cannot meet the requirements. Even steam cleaning and high-pressure water jet cleaning can not meet the demand for higher cleanliness. Therefore, this is the reason why ultrasonic cleaning is increasingly used in various industries.

Application areas of ultrasonic cleaning:

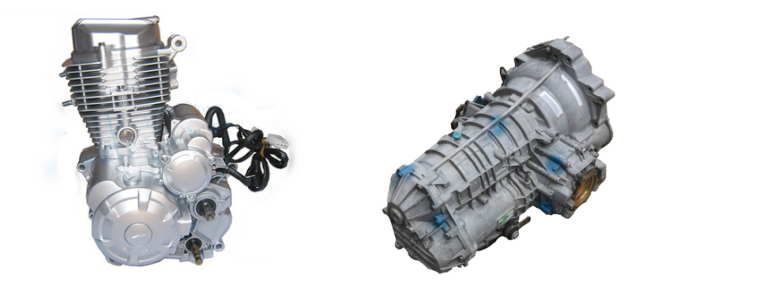

1. Machinery industry: removal of anti-rust grease; cleaning of measuring tools and cutting tools; degreasing and rust removal of mechanical parts; cleaning of engines, carburetors and auto parts, dredging and cleaning of filters and screens, etc.

2. Surface treatment industry: degreasing and rust removal before electroplating; cleaning before ion plating; phosphating treatment; removing carbon deposits, oxide scale, polishing paste, surface activation treatment of metal workpieces, etc.

3. Medical industry: cleaning, disinfection, sterilization of medical equipment, cleaning of laboratory utensils, etc.

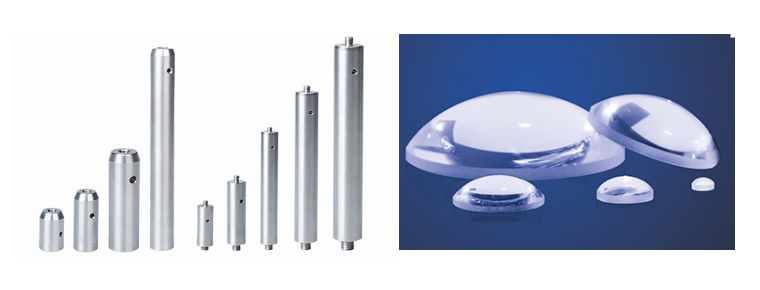

4. Instrumentation industry: high cleanliness cleaning of precision parts, cleaning before assembly, etc.

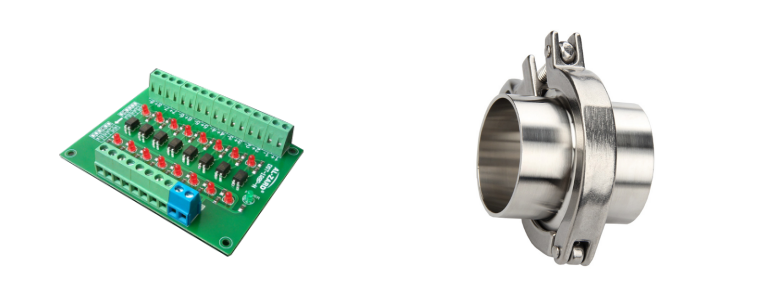

5. Electromechanical and electronic industry: the removal of rosin and welding spots on printed circuit boards; the cleaning of high-voltage contacts, terminals and other mechanical and electronic parts, etc..

6. Optical industry: degreasing, sweating, dust removal and so on for optical devices.

7. Semiconductor industry: high cleanliness cleaning of semiconductor wafers.

8. Science, education and culture: cleaning and descaling of laboratory utensils such as chemistry and biology.

9. Watches and jewelry: remove sludge, dust, oxide layer, polishing paste, etc.

10. Petrochemical industry: cleaning and dredging of metal filters; cleaning of chemical containers, exchangers, etc.

11. Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc.

12. Others: Ultrasonic cleaning: remove pollutants, dredge small holes, such as cleaning seals, antique restoration, and dredging of automobile electric nozzles.

Ultrasonic stirring: speed up dissolution, improve uniformity, speed up physical and chemical reactions, prevent over-corrosion, speed up oil-water emulsification, such as solvent dye mixing, ultrasonic phosphating, etc.

Ultrasonic coagulation: accelerated precipitation and separation, such as seed flotation, beverage slag removal, etc.

Ultrasonic sterilization: kill bacteria and organic pollutants, such as sewage treatment, degassing, etc.

Ultrasonic pulverization: reduce the particle size of the solute, such as cell pulverization, chemical testing, etc.

Ultrasonic sealing: Eliminate interstitial gas and increase overall density, such as dipping paint.